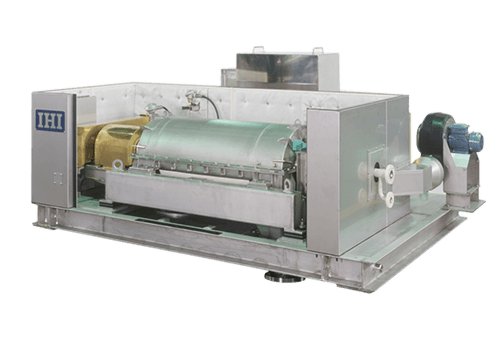

Screw Decanter Centrifuges

The IHI Screw Decanter Centrifuge are developed with the latest high speed rotation technology. IHI’s screw decanter type centrifuges are widely used in various fields with water treatment and manufacturing processes. The centrifuges handle a wide range of slurry types and the treatment capacity is extended because of their continuous operation.

Some of the process fields where the IHI Screw Decanter Centrifuges are in operation are:

- Petroleum and gas industry (MEG- and MUD treatment etc,)

- Waste water

- Chemicals such as paint, drugs, oil and fat, fertilizer and printing plating

- Gypsum for desulfurization from exhaust gas

- Marine product processing

- Agricultural product processing

- Brewing and bread baking

- Pulping

- Iron and steel industry

- Wet type dust collector

IHI have developed a pressure resistant and air tight decanter centrifuge by implementing non-contact shaft seals. There is no loss of power from the seals, it ensures a long life span and contamination to atmosphere will not occur. This design is recommended for solvents, poisonous substances and other hazardous materials.

Guinard Centrifuges

The Guinard Centrifuge is a solid-liquid separator manufactured with IHI’s high speed rotation technology using the fully automatic and continuous centrifugal method. The basket type separator is suitable for dehydrating comparatively coarse solids and is capable of washing separated solids with our original washing system.

Slurry is fed from the top of the casing inside of the rotator and the liquid is spread out by centrifugal force. Particles are caught up by the screen inside the basket where a scraper is also installed. The screen and the scraper rotate at high speed in the same direction at a constant relative rate of speed. Separated solids are scraped away from the rotator and discharged from the outlet at the bottom of the machine.

The IHI Guindard centrifuges comes in six different line-ups:

- N-Type (Short Basket type): Standard type, equipped with large slurry feed inlet and suitable for treating slurries containing coarse solids.

- H-type: (Tall Basket type): Suitable for treating low concentration slurries or viscous liquids.

- HL-type (Single-stage washing type): Capable of washing the separated solid by spraying a washing liquid.

- HL2-type (Two-stage washing type): For more efficient performance of solid washing. You can also use two different types of washing liquid

- HLS-type (Washing liquid separation type): Separated liquid and Washing Liquid are collected separately.

- HLS2-type (Two-stage washing/liquid separation type): After the two-step washing, clarified liquid and washing liquid II/washing liquid I are collected separately.

Leaf Filters

The IHI Leaf Filter is a horizontal type pressure filter. Inside the pressure-resistant vessel, filter leaves are arranged horizontally on a vertical shaft. A motor drive rotates the shaft and cakes on the leaves are blown away by centrifugal force. The bottom of the vessel has an inverted cone shape for smooth cake discharging.

The IHI Leaf Filter combines excellent filtration performance and fully automatic operation. Residual liquid, the long-standing problem for a pressure filter, is also completely filtered by IHI’s original Rest Volume Filtration system.

For more information about the IHI Leaf Filters, you can visit the offical website of IHI – press here

The IHI Leaf Filters comes in three different line-ups:

CFR Type

This is the IHI Leaf Filter standard type capable of drying filtrated cake by steam, air and N2 gas and discharging it automatically. The filter can deal with slurry under high pressure, high temperature and high viscosity and can be fitted with a mechanical seal for virulent or volatile slurry.

For a more detailed presentation of the CFR Type, press here

CFA Type

The fundamental structure of the CFA type is the same as that of the CFR type with the additional possibility to discharge the cake automatically as a slurry.

For a more detailed presentation of the CFA type, press here

LR Type

The performance of the LR type is the same as the CFR type with the possibility for Dreg Removal and is capable of CIP Automatic Washing. It is suitable for Food, Chemicals, Medicines, Pharmaceuticals and Beverage Industry.

For a more detailed presentation of the LR Type, press here